"I'm trained to catch defects before they become defeats" - Inspector 34 (Pete and Pete, 1994)

In addition to our OnDemand, reference driven digitization program, the D-Team has been engaged in some very large digitization projects over the last few years as part of our Special Projects program. These projects include materials such as the Rockefeller Foundation Officer Diaries, Rockefeller Brothers’ Fund Annual Reports, the Foundation for Childhood Development microfilm, the Rainbow Room Scrapbook, and selections of various collections for the Centennial project and the PUMC. All in all, we’ve digitized about 269,000 pages of archival material (both textual & photographic).

This massive amount of digitization was made possible by outsourcing to Hudson Microimaging (HMI), a digital imaging vendor located up in Port Ewen, where they have the equipment and staff necessary to accomplish digitization at this scale.

An overhead scanner, such as those used at HMI. (image by jmignault, some rights reserved)

While this arrangement has allowed us to digitize much larger selections of material in a MUCH shorter time, (than if we used in-house resources), we still face the challenge of assuring that the huge amount of files we receive from HMI meet our stated specifications. We do this by implementing a QA system and performing QC on the files produced.

Lucy and Ethel performing "QC" on chocolates at a candy factory. (I Love Lucy, 1952)

Quality Assurance, referred to commonly as “QA” is a process implemented to verify that that the systems you have in place are producing a quality product.

Quality Control, called “QC”, is a system of inspecting a product to see if it meets the standards and specifications that it should.

In other words (to apply these terms to our “product”: digital surrogate files of archival materials), QA is looking at the entire digitization process, checking for issues that could affect the outcome, and QC is looking at the surrogates, checking that they conform to our standards and are faithful representations of the original material.

How is this implemented at the RAC?

QA begins with setting up a workflow that supports the creation of high quality digital surrogates by maintaining standards at every step of the way:

- Materials are chosen based on a set of criteria that, among other things, looks at how effectively they can go through the digitization process. By avoiding projects that will produce inferior digital surrogates we are allowed to focus on material that has a higher likelihood of being digitized successfully to our standards.

- If necessary, items will be tended to and prepared (cleaned, rehoused etc.) prior to digitization, to be sure they are captured in the best possible condition.

- A digital imaging vendor is selected by investigating that their standards, practices, equipment, expertise and QA processes are up to our standards. This includes visiting their facilities if possible.

- Specifications are assigned and documented and then negotiated with the digital imaging vendor to create a contract. These specifications are used when checking the digital surrogates for compliance.

- Once we’ve received the files (usually via external hard drive) we verify that the data has transferred without any corruption, that the naming convention and directory structure outlined were implemented correctly, and then perform a QC review of the digital surrogates themselves.

- The QC review entails screening a set percentage of the files. This can range from 5% to 100% depending on the extent and variability of the material being digitized. Randomly selected files are opened (to ensure they are functional) and then their resolution, size, editing and other characteristics are checked against the specifications outlined in the contract. The names of all files opened and reviewed are recorded, with any deviations from the specifications noted.

- Any deviations from the expected results are corrected. This can mean anything from editing individual files in-house to having the digital imaging vendor re-do the project.

- Once the files have passed all checks, they are approved to be ingested into Archivematica and can potentially be used by our patrons.

By making sure that all of our digitization efforts go through each of these steps and also meet all of these requirements, we can be assured that our digital repository will consist of the highest quality digital surrogates that our resources will allow. We can also have the confidence to ensure users of these files that the surrogates we’ve created are faithful representations of the original items they were derived from.

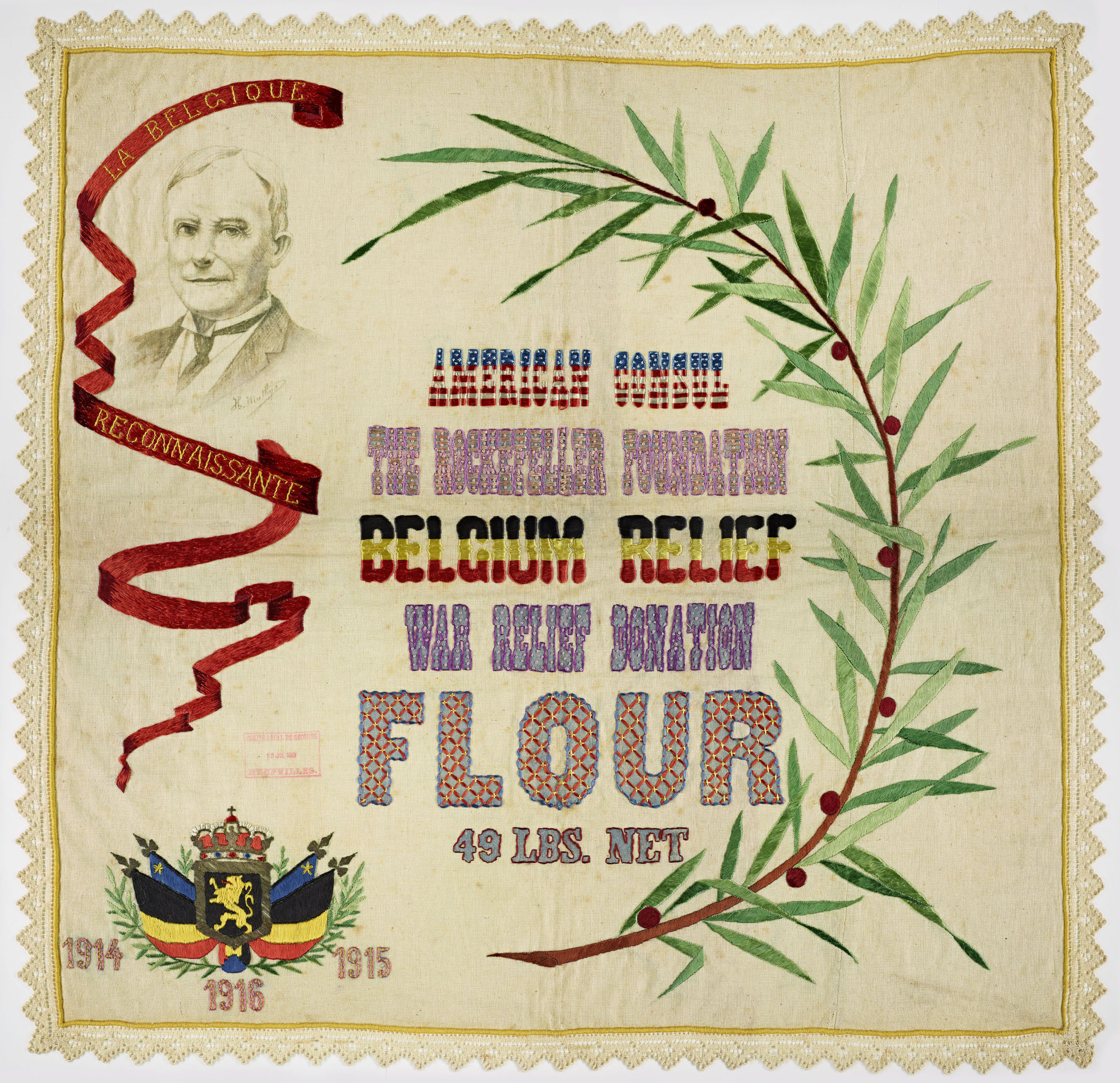

An example of a digital surrogate made from an item that would otherwise be difficult to provide access to. Even though this is a reduced resolution & size "Service_Edited" derivative, check out the detail & quality we are making available to our users.